As the need for efficient filtration systems continues to grow, the demand for cartridge filter winding machines has witnessed a significant surge. These machines play a crucial role in producing high-quality filters that are widely used across various industries. In this article, we will explore the industry trends and analyze the importance of cartridge filter winding machines.

The Versatility and Efficiency of Cartridge Filter Winding Machines

Cartridge filter winding machines offer exceptional versatility and efficiency in manufacturing filters. They enable precise control over factors such as diameter, length, pleat depth, and spacing during the winding process. This ensures consistent quality and performance of the filters produced.

Moreover, these machines can handle different types of materials like polypropylene (PP), glass fiber, stainless steel wire mesh, etc., allowing manufacturers to cater to diverse filtration requirements across industries such as water treatment plants, pharmaceuticals, food processing units, automotive manufacturing facilities, and more.

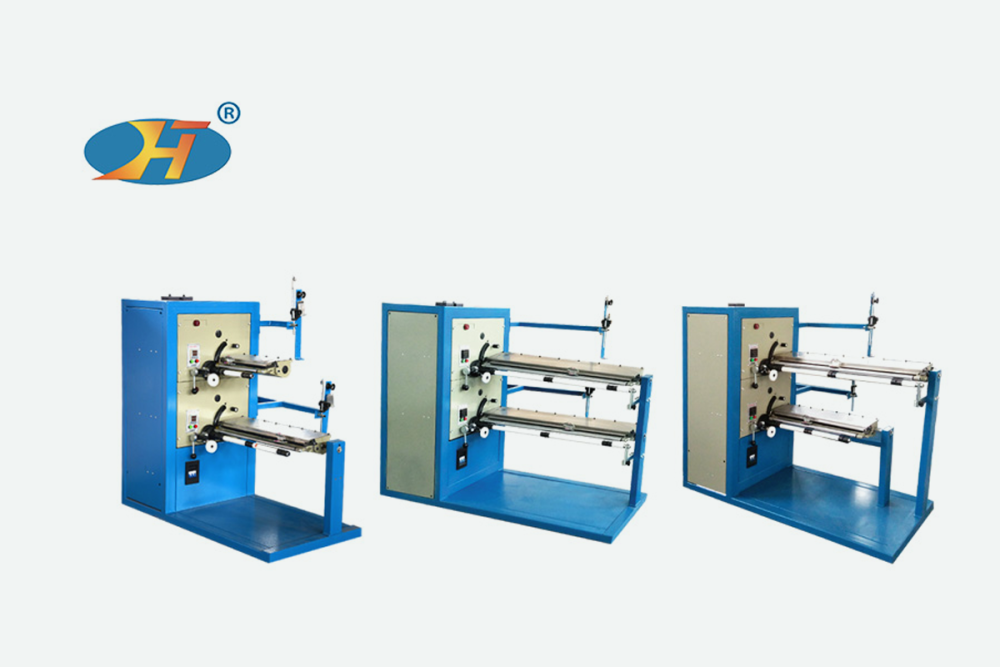

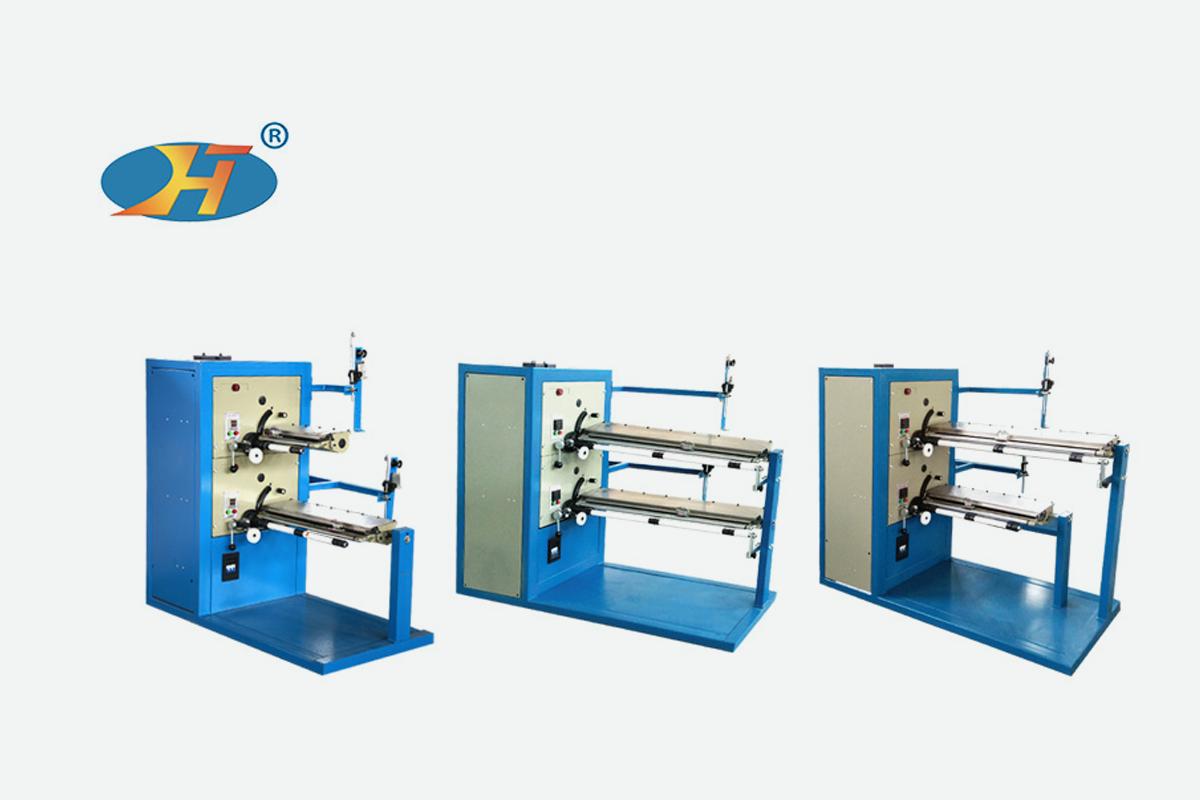

Hongteng: A Leading Manufacturer in Cartridge Filter Winding Machines

Hongteng is one of the prominent manufacturers specializing in cartridge filter winding machines. With years of experience and expertise in this field, Hongteng offers state-of-the-art machinery that meets international standards.

Their range of cartridge filter winding machines incorporates advanced technologies like PLC control systems and servo motors for precise operation. Additionally, they provide customizable options to meet specific client needs while ensuring optimal productivity.

The Significance of PP Melt Blown Filter Machine

In conjunction with cartridge filter winding machines’ rising demand is an increased focus on pp melt blown filter machine technology. This machine plays a vital role in producing melt blown filters made from polypropylene material – known for its excellent filtration efficiency.

The PP melt blown filter machine utilizes a unique process to create fine fibers that form a dense web-like structure, resulting in filters with exceptional dirt-holding capacity and high flow rates. This technology has gained immense popularity in industries such as water purification, chemical processing, and pharmaceutical manufacturing.

Conclusion

The cartridge filter winding machine industry is witnessing significant growth due to the increasing demand for efficient filtration systems across various sectors. Hongteng’s expertise in manufacturing these machines ensures the availability of high-quality equipment that meets industry standards. Additionally, the emergence of PP melt blown filter machines further enhances the capabilities of cartridge filters by providing superior filtration performance. As industries continue to prioritize clean and safe processes, investing in advanced machinery like cartridge filter winding machines becomes crucial for manufacturers seeking optimal filtration solutions.